Editor’s Note: This post, originally published on December 21, 2020, has been thoroughly revised and updated to ensure accuracy and comprehensiveness.

When it comes to waterproofing concrete, the joints are where the battle against water infiltration peaks. These joints usually are the weakest points of the structure and are particularly vulnerable to water penetration. Failure to protect such an area can result in the wear and tear of concrete and any steel used for reinforcement. This is where the Hydrotite hydrophilic surface comes into play; changing the face of how concrete joints will be protected from water damage.

Your Next Project, Simplified with Danterr!

Enter your email to explore our top-quality construction solutions. We’re here to support your project’s needs with innovative, sustainable products.

Catalogue Form

The Science Behind Hydrotite

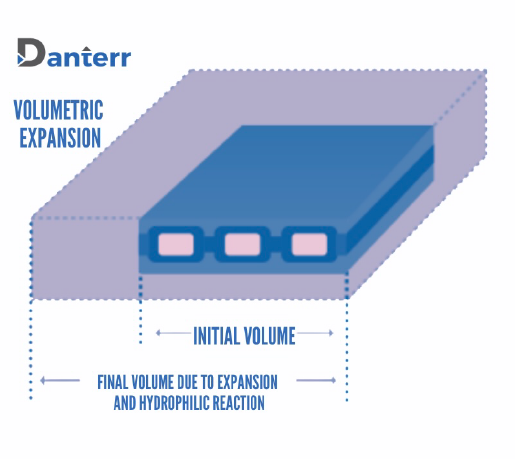

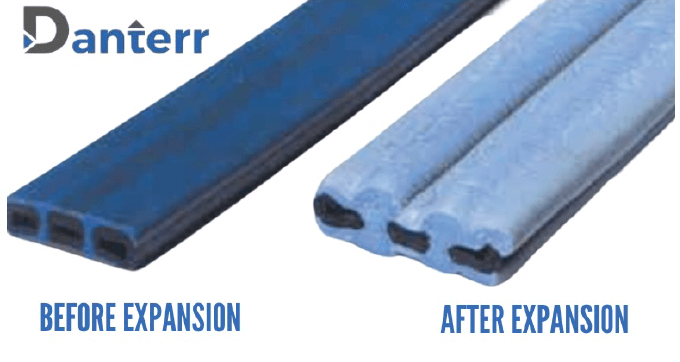

Hydrotite is engineered from a unique hydrophilic polymeric material, which increases its volume when exposed to water. This expansion capability is crucial for maintaining a watertight seal in concrete joints. The co-extruded profiles of Hydrotite direct the expansion across joints increasing the lasting water sealing by contact surface pressures.

Exceptional Expansion Capacity

Hydrotite has an advantage over other water absorption gel bead products because they swell up to 8 times their initial size when contacted with water. This gives an initial compression sealing and allowance for future joint movements which helps the sealing performance over time.

Key Benefits of Hydrotite

Delay Coating for Optimal Performance

This slow-releasing coating is helpful during the building process since it minimises swelling, which is critical for the optimal performance of Hydrotite. This coating gives enough time for the new concrete to harden before the Hydrotite starts swelling up, avoiding potential issues with un-cured concrete or unexpected wet conditions on-site.

Robust and Durable

Unlike PVC water stops, which are less tolerant to typical concrete construction practices, Hydrotite is capable of expanding to accommodate the concrete shrinkage without affecting its sealing performance. Moreover, they yield greater results than Bentonite waterstops that swell only 1-to-2 times their original volume and often fail under hydrostatic pressure.

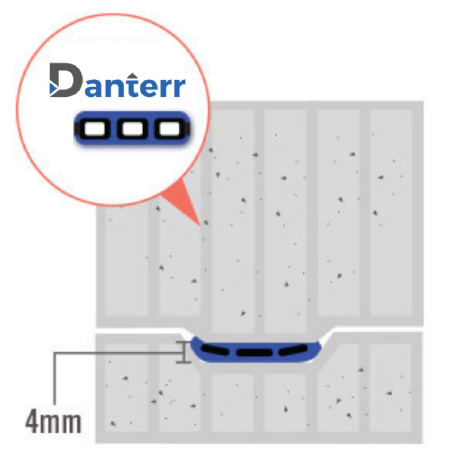

Initial compressed seal

The way Hydrotite is engineered with rubber elasticity and a hollow core allows an initial compressed seal between adjacent surfaces during construction.

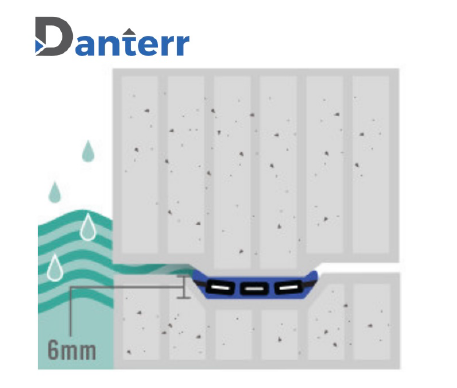

Hydrophilic reaction

When Hydrotite is met with water, a hydrophilic reaction occurs. Water is attracted and spread evenly, producing a secondary expansion following contact with water, ensuring a water-tight seal is maintained.

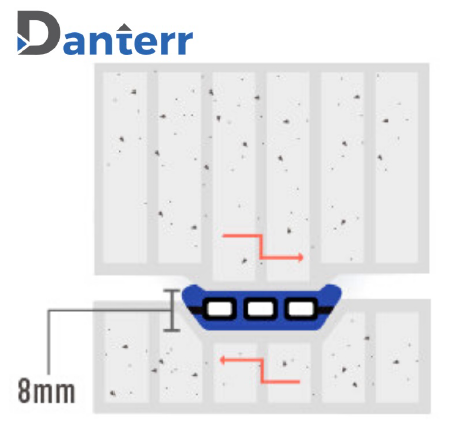

Residual expansion

Should the future produce any related structural movement, Hydrotite will have provided residual expansion to maintain a high contact surface pressure and watertight seal.

Expansion delay coating

One of the best features of Hydrotite is its delay coating. The coating on Hydrotite delays premature expansion should the product be met with rain or groundwater before installation. The delay expansion coating also allows freshly poured concrete to cure before expansion begins.

Comparative Advantages Over Competitors

Hydrotite vs. PVC Waterstops

PVC water stops often fall short in adapting to concrete shrinkage and movement. Compared with Hydrotite, it has a poor swelling property and shrinks depending on the environmental conditions while Hydrotite exhibits consistent and reliable sealing properties.

Hydrotite vs. Bentonite Waterstops

Bentonite-based waterstops are also very sensitive to swelling and have been observed to deteriorate after some time or when exposed to water. Hydrotite has also demonstrated a thus controlled and significant expansion and durability with high resistance to microbial vulnerabilities.

Sustainability and Future Projects

Supporting Australia’s Water Infrastructure

Hydrotite is not just the best product in the market as an application but equally a crucial part of the solutions for Australia’s freshwater problems. As Australia looks forward to a clean water future with more federal funding for dam and catchment settlements set to support developments in water storage and supply, Hydrotite is set to play a vital role in these large-scale infrastructure projects.

Major Projects Utilizing Hydrotite

- Snowy 2.0 Hydroelectric Project: Hydrotite was integral in ensuring the water-tight integrity of this large-scale hydroelectric project, providing a reliable seal for the numerous joints involved, thereby enhancing the project’s longevity and efficiency.

- Rookwood Weir Project: This critical water infrastructure project utilised Hydrotite to enhance the durability and waterproofing of the concrete structures involved, securing a reliable water supply for the region.

- Canberra Metro Light Rail: Hydrotite was employed in the construction of the Canberra Metro, ensuring long-term joint integrity and waterproofing of the rail infrastructure, contributing to a sustainable public transport system.

- WestConnex Tunnel: Hydrotite provided exceptional sealing in the extensive tunnelling work of the WestConnex project, ensuring protection against water infiltration and enhancing the durability of the tunnel structure.

- Sydney Gateway Project: Hydrotite played a key role in this transformative project, enhancing the durability and water-tightness of the new infrastructure, which is vital for improving Sydney’s traffic flow.

- Mona Vale Road East Upgrade: Hydrotite was used to ensure the joints in this road upgrade project remained secure and leak-proof, enhancing the road’s longevity and safety.

- Rozelle Interchange: This project utilised Hydrotite to revolutionise Sydney’s motorway network with improved waterproofing of the concrete structures, ensuring long-term durability.

- Tolosa Water Supply Upgrade: Hydrotite was crucial in waterproofing the concrete joints in this water supply upgrade project, ensuring a secure and reliable water supply for the community.

- Sydney Light Rail: Hydrotite ensured robust waterproofing for the joints in this major public transport project, enhancing the durability and efficiency of the rail system.

- M4 East Western Motorway: Hydrotite was used to secure the concrete joints in this major motorway project, ensuring long-term protection against water damage.

- INPEX Project Darwin: This large-scale project used Hydrotite for superior joint waterproofing, enhancing the project’s overall integrity and longevity.

- Sydney Metro Northwest: Hydrotite ensured long-term waterproofing for the joints in this extensive metro project, contributing to the reliability and efficiency of the transport system.

- Hornsdale Wind Farm: Hydrotite was used to waterproof the concrete joints in this wind farm project, supporting sustainable energy production.

- Kangaroo Creek Dam Upgrade: Hydrotite provided excellent waterproofing for the concrete joints in this dam upgrade, ensuring the structure’s long-term durability and functionality.

- Caulfield to Dandenong Level Crossing Removal: Hydrotite was essential in ensuring the joints remained leak-proof in this level crossing removal project, enhancing safety and efficiency.

- West Gate Tunnel Project: Hydrotite played a critical role in waterproofing the concrete joints in this major tunnel project, ensuring the tunnel’s durability and safety.

- Moorebank Logistics Park: Hydrotite ensured the concrete joints in this logistics park remained secure, supporting efficient and reliable operations.

- Northern Road Upgrade: Hydrotite was used to enhance the waterproofing of the joints in this road upgrade project, ensuring long-term durability and safety.

- Sydney Metro Public Transport Project: Hydrotite was utilised to ensure the joints in this major transport project remained leak-proof, supporting the system’s reliability and efficiency.

- Nepean River Bridge: Hydrotite provided robust waterproofing for the concrete joints in this essential bridge project, ensuring long-term durability and safety.

Conclusion

At Danterr, we are proud to be Australia’s authorised distributor of Hydrotite hydrophilic surface solutions. This innovative product embodies our commitment to quality, and sustainability, delivering superior products and providing the best chance concerning the success of our clients’ projects. By choosing Hydrotite, you are giving assurance that the construction you are involved in is protected with the most suitable and effective waterproofing material in the market which will not fail but will provide long-term durability and peace of mind.

Hydrotite revolutionises concrete joint protection by improving the quality of your projects in anticipation of the weather and environmental conditions to withstand. Learn how switching to Danterr translates to better concrete innovation dedicated to providing top-quality concrete products for every construction size. Browse through our vast product offering of water-blocking solutions and find out how we can help make your concrete structures robust and leak-proof. Contact Danterr today!

📞: 1800 262 383

📧: sales@danterr.com

For more information or to discuss your project needs, contact us at 1800 262 383 or email sales@danterr.com.

Frequently Asked Questions:

Concrete joint waterproofing prevents water infiltration that can lead to deterioration of the concrete and embedded steel reinforcements, ensuring the longevity and durability of the structure.

Hydrophilic waterstops are materials that swell upon contact with water, creating a tight seal to prevent water ingress in concrete joints.

Hydrotite expands up to eight times its original size upon water contact, filling gaps and creating a watertight seal in concrete joints.

A delay coating prevents premature expansion of the waterstop during construction, ensuring it expands only when needed after the concrete has cured.

Hydrotite adapts better to concrete shrinkage and movement, maintaining a reliable seal, whereas PVC waterstops are less tolerant to these changes.

Yes, Hydrotite is ideal for tunnels and underground structures due to its ability to withstand high hydrostatic pressure and repeated wet-dry cycles.

Common applications include dams, reservoirs, tunnels, basements, and other water-retaining structures.

Waterproofing products, by extending the life of structures and reducing maintenance needs, contribute to sustainability by minimizing resource use and waste.

Synthetic rubber in Hydrotite offers superior durability, resistance to microbial attack, and maintains expansion properties over time compared to natural rubber.

Yes, Hydrotite is suitable for use in potable water structures, providing a reliable seal to prevent contamination and leakage.

Danterr’s hydrophilic waterstops, such as Hydrotite, play a crucial role in large-scale construction projects. Key features include high expansion capacity, delay coating for optimal performance, and robust durability. These attributes ensure reliable, long-term waterproofing and joint protection, which are essential for the structural integrity and longevity of projects like tunnels, roads, and water infrastructure. By using Hydrotite, construction projects benefit from enhanced durability and reduced maintenance needs, contributing to overall project success.

Stay Updated with Danterr!

Subscribe to Our Newsletter for the Latest in Construction Solutions